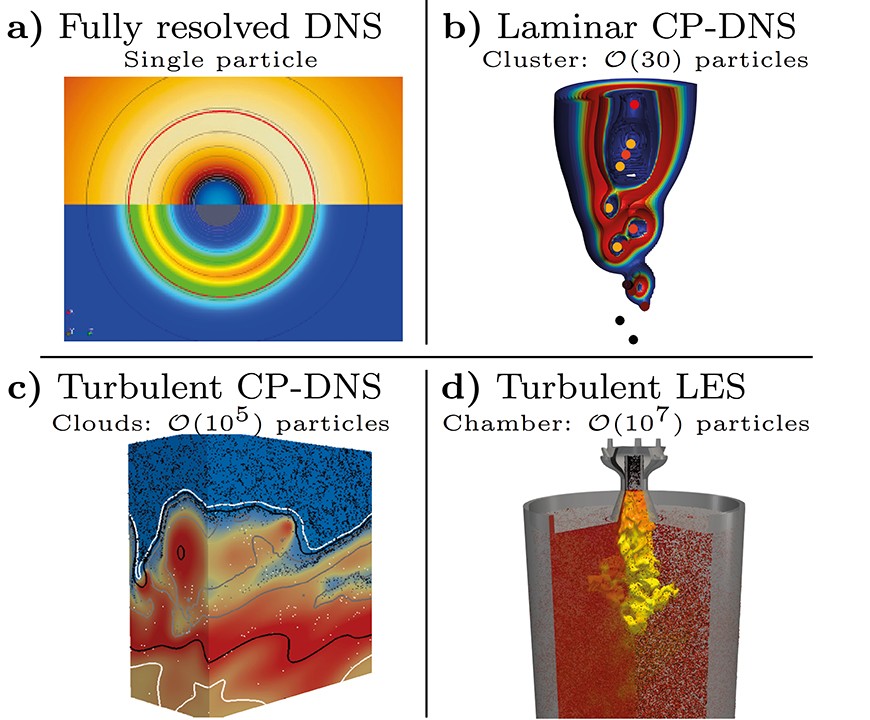

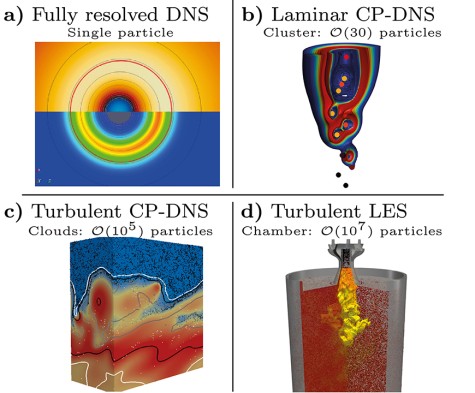

We will consolidate the novel single particle and particle cluster models into a single computational framework and perform CP-DNS studies for a particle-laden turbulent shear layer representative of the near-burner region. This mixing layer setup will enable quantification of the effects of turbulent intensities, particle load, and pressure and their interplay with the microscopic and macroscopic flame structure.

Based on these results, LES techniques will be developed to balance accuracy and computational cost for system-scale simulations. The ultimate goal is to predict and analyze physicochemical processes in pressurized aluminum-steam combustion chambers at the laboratory scale. In-situ optical diagnostics will be used for high-resolution measurement of particle-laden jets that provide insights into turbulent flame dynamics at higher Reynolds numbers.

The novel experimental information will include how the slip between particles and gas phase impacts particle heat-up and reaction enhancement and how the particle-particle interaction influences reaction zone structures. Employing these tailored experiments for validation will demonstrate the capability of high-fidelity LES for computing turbulent aluminum-steam flames.

Ultimately, this simulation framework will facilitate predictive designs of aluminum-steam combustion processes.