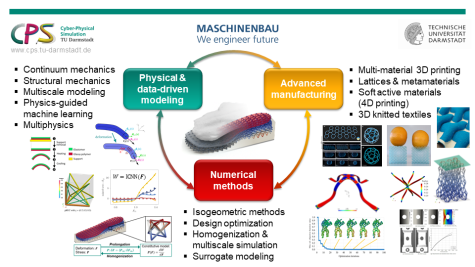

With these novel methodologies, we aim to (1) enable more accurate, efficient, flexible, and robust numerical modeling and simulation; (2) bridge the gap between computer-aided design, simulation, design optimization, and fabrication; and (3) combine classical, physics-based approaches with data-driven, physics-informed machine learning.

These developments are crucial for the engineering adoption of many advanced and emerging manufacturing and materials technologies, and to fully exploit their potentials. Furthermore, they are integral parts of the development of digital twins of cyber-physical systems that facilitate more efficient and sustainable product development and operation.

Topics

- Physics-based modeling and data-driven model development for engineering problems:

- Nonlinear continuum mechanics (finite deformations, hyperelastic materials, viscoelasticity, plasticity, contact)

- Structural mechanics, in particular 3D beam models

- Multiscale modeling with classical and generalized continuum theories

- Multiphysics models that couple mechanical with thermal, electro-magnetic, or chemical effects

- Physics-guided machine learning for constitutive and surrogate modeling

- Development of advanced computational methods for engineering simulation and design optimization:

- Isogeometric analysis, finite element and collocation methods

- Topology, shape, design and sizing optimization

- Homogenization methods for multiscale simulation

- Surrogate modeling concepts for dynamical systems

- Advanced manufacturing applications and seamless integration of computational design, optimization and fabrication:

- Multi-material 3D printing of functionally graded structures

- 4D printing with soft active materials

- Functional, 3D printed lattice structures and metamaterials

- 3D knitting of functional textiles

- Numerical and Experimental Investigation of Photopolymers in additive manufacturing:

- Study of materials and manufacturing processes in 3D printing with a focus on polymers.

- Mechanical characterization and material modeling of 3D printed polymers

- Elastic, hyperelastic, viscoelastic, and elasto-visco-plastic material modeling in large and small deformations

- Investigation of the influence of process parameters on mechanical properties of printed structures

- Design and optimization of 3D printed structures and process

Funded projects

| Project title | Partners | Duration | Sponsor |

|---|---|---|---|

| CellDistinct – Targeted cell distinction with optimally graded micro-lattice structures | Prof. Dr. Andreas Blaeser (TU Darmstadt) | 2023-2025 | HMWK (LOEWE 5) |

| OptiMag – Optimized magnet design for cooling machines |

MagnoTherm Solutions GmbH, Prof. Dr. Sebastian Schöps (TU Darmstadt) |

2023-2025 | HMWK (LOEWE 3) |

| A thermodynamically consistent, inelastic constitutive modeling framework based on artificial neural networks | - | 2022-2025 | DFG |

| Microlattice structures for lithium-ion battery electrodes: Chemo-mechanical beam modeling of diffusion-induced instabilities and optimal design | Prof. Dr Bai-Xiang Xu (TU Darmstadt) | 2021-2024 | DFG |

| Data-driven methods for nonlinear multi-scale computational mechanics | Prof. Dr. Kristian Kersting (TU Darmstadt) | 2019-2021 | TU Darmstadt |