We research ...

… on pioneering technologies for a climate-friendly, reliable, economical energy supply.

… on innovative concepts for the use of residual materials towards a closed-loop circular economy.

… on resource-friendly, sustainable processes to replace fossil input materials.

… on increasing the efficiency of energy transition processes.

… on methods for saving energy in buildings, process plants and infrastructure systems.

Videos on the energy research focus

Achieving carbon neutrality is one of the most important goals of our society. We are working on not simply having to incinerate waste materials, but to chemically recycle these waste materials in order to generate a product from them; in short, also to be referred to as Waste-to-Value. Find out more in the video!

The energy transition is one of the most pressing problems of our time. The aspect of a climate-neutral retrofit of existing infrastructure is increasingly coming into focus. The Clean Circles project aims to make existing thermal coal-fired power plants CO2-free by retrofitting them… Find out more in the video!

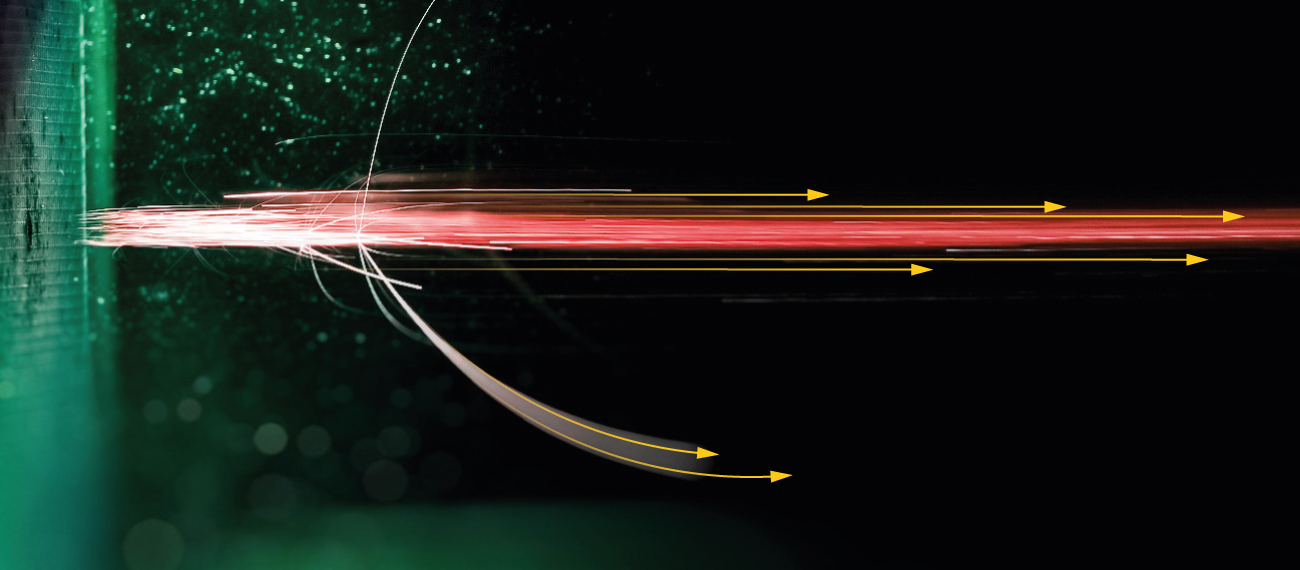

The Collaborative Research Centre TRR 150 investigates the interaction of chemical reactions with transport processes (turbulence and diffusion) in the presence of a wall. The aim is to gain a better understanding of the processes and to develop mathematical models based on this. These are then integrated into overall models in order to demonstrate this predictive capability using suitable systemic considerations… More in the video!

Many energy and process engineering processes involve mixtures of gases and liquids. In the plants, dynamic wetting and dewetting of the solid walls always takes place, which significantly influences the efficiency of the energy and material conversion processes. The aim of the CRC 1194 is to fundamentally understand the interactions between the wetting and dewetting processes and the heat and mass transfer and, on this basis, to specifically increase the efficiency of multiphase processes… More in the video!