Design of an Experimental Setup to Analyze the Effects of Groove Icing on Aircraft Aerodynamics

Advanced Design Project (ADP)

After flying in a freezing condition, the aircraft wings get to a temperature below 0°C. When these wings interact with a cloud, it develops ice structures. The unprotected area on the wing poses risk of runback icing. One such areas and our area of interest is the grooves near the flaps and spoilers. Any real-life groove must have a groove curvature, which is also important while studying liquid transport. In the literature, such a groove has already been studied under an isothermal condition. However, the effects of heat transfer and phase change, which is very prominent in aircraft icing applications, has never been discussed. To capture these effects, a known but highly wettable surface must be used. As ice is super-hydrophilic, which tend to increase the rivulet spread and hence also increases the ice effected zones inside the grooves

Task description

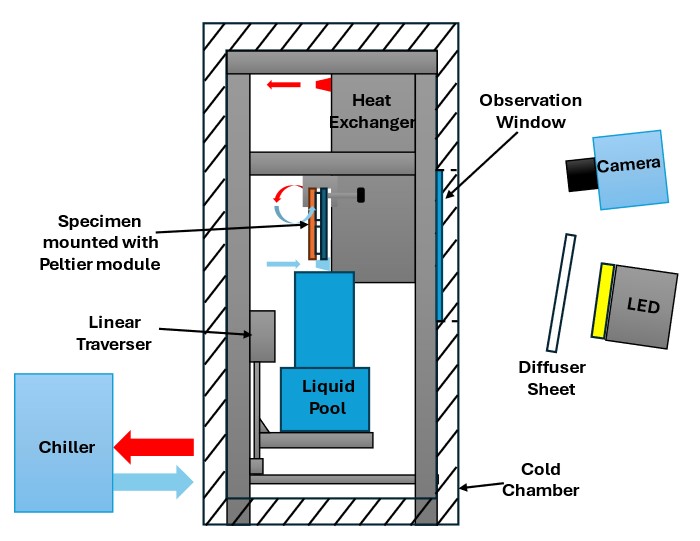

The main objective of this ADP project is to establish a method of manufacturing a well-defined ice groove and characterizing it using a contactless measurement technique. The aim is to determine the roughness, curvature and opening angle of the groove. The ice groove should then be implemented and tested in the existing set-up configuration.

Requirements:

- High motivation and interest in experimental work

- Knowledge of LabView/CAD (Siemens NX, SolidWorks, …)

- Hands-on experience with sensors, ARDUINO, image-processing (MATLAB) would be beneficial

Tasks:

- Reviewing the literature to get familiarized by the topic

- Designing and manufacturing of a well-defined groove geometry on ice surfaces

- Devising a contactless technique to measure the ice thickness and groove geometry with acceptable accuracy

- Conducting and post-processing the experimental results