Process simulation of the iron energy storage cycle with AspenPlus

Energiespeicher für erneuerbaren Strom: Prozesssimulation des Eisenkreislaufs zur Energiespeicherung mit AspenPlus

Masterthesis

The topic

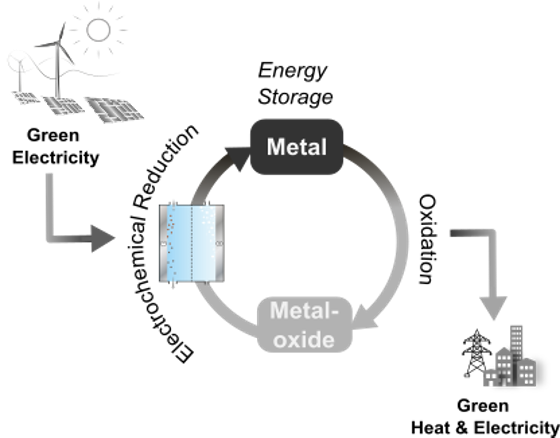

Large-scale energy storage is a critical challenge for achieving a green economy. The metal energy cycle presents a promising approach by allowing cyclic combustion and reduction processes without CO2 emissions. Among potential energy carriers, iron powder stands out due to its favorable combustion characteristics. To accurately compare the iron cycle and its different iron reduction methods to competing energy storages, a simulative process analysis is needed.

Your Task

At VES we investigate the direct electrochemical reduction of iron oxide slurry. To evaluate this approach a detailed understanding of the system at process scale is required. During your thesis you will develop a simulative model of the iron cycle, focusing on electrochemical reduction. With this, you will give insight into the cycle and give valuable information on its efficiency and viability. Furthermore, you will evaluate the potential of direct iron electrolysis as the reduction step.

Work packages

• Literature research.

• Setting up the iron cycle in Aspen using literature.

• Modeling the electrochemical reduction of iron.

• Evaluate the process cost and efficiency.

What you should bring

• Experience with Simulations is helpful, preferably with AspenPlus.

• Independent and reliable working style.

• A cake :)

What we offer

• You will learn about process engineering and electrochemical methods.

• Working in a team with scientific staff.

• Gain hands-on experience in an engineering task.

• Close supervision.

If you have any questions, please do not hesitate to contact us personally, by phone or via email (German or English).