Simulation of the Combustion of Aluminum in Steam

Masterthesis

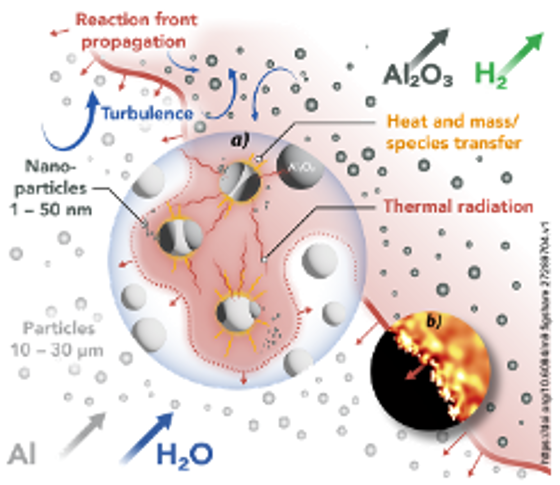

At the Simulation of reactive Thermo-Fluid Systems research group, we study the combustion of metallic fuels as chemical energy carriers, which offer a sustainable alternative to fossil fuels. While aluminum powder is already used in high-performance applications such as rocket engines, there are still significant gaps in understanding the underlying physical and chemical processes, as well as in numerical modeling. In particular, the gas-phase combustion of evaporated aluminum with air or steam differs significantly from other metal fuels and requires further investigation.

This thesis focuses on the numerical simulation of a single aluminum particle to better model its evaporation and combustion processes. Key aspects include:

• Evaporation of aluminum and subsequent oxidation of aluminum vapor with steam,

• Formation aluminum oxide nano-particles,

• Deposition of aluminum oxide on the particle surface and resulting changes in particle shape.

The work will involve extending existing numerical models, particularly in the areas of:

• Transport of nanoscale combustion products,

• Dynamic evaporation processes,

• Temporal evolution of particle size and morphology.