The New Iron Age Begins – Now at Technical Scale! Scaling Iron Combustion with Scientifically Sound Reduced-Order Modeling

Publication

07.03.2025

The New Iron Age Begins – Now at Technical Scale! Scaling Iron Combustion with Scientifically Sound Reduced-Order Modeling:

Fundamental research on single particle combustion is essential for developing large eddy simulation (LES) models of turbulent flames. But what happens when the reactor reaches meter-scale dimensions and LES becomes infeasible?

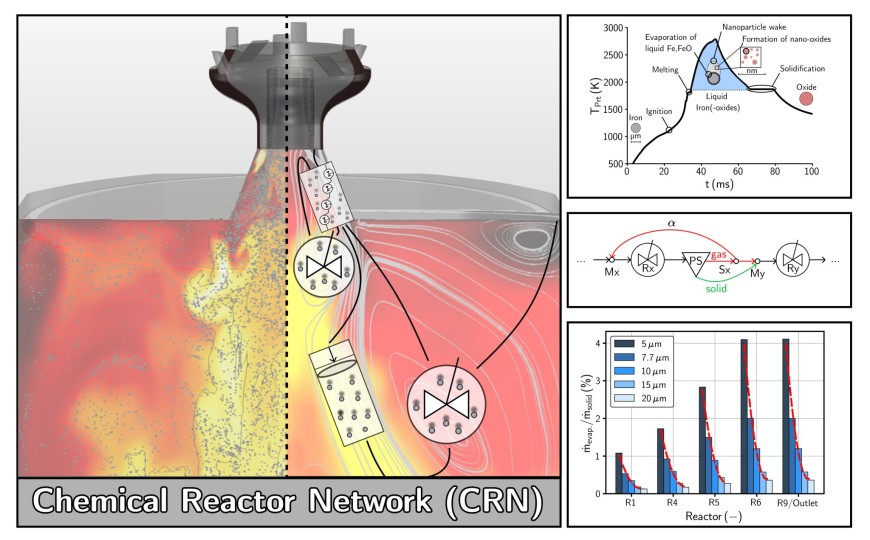

The solution: Chemical process engineering provides a powerful tool— reduced-order models (ROM), also known as compartment models or chemical reactor networks (CRN).

As a key step toward scaling this innovative technology, we have extended the CRN approach to iron combustion, validating its application from single-particle oxidation to gas-assisted iron dust flames in a laboratory-scale combustor.

Our Contributions:

- Adapted the CRN approach for solid carbonaceous fuels to model iron dust flames

- Developed a CRN configuration capturing laminar iron flame structures

- Conducted sensitivity studies on particle size, oxygen availability, and gas temperature in a swirl burner

Key Findings:

- Particle size significantly influences evaporation rates inside the combustor

- Local oxygen distribution is crucial for FeO-to-Fe₃O₄ oxidation, impacting iron conversion

- Gas temperature is a major driver of NOx formation and evaporation

This study demonstrates the power of CRN modeling in predicting gaseous and particulate pollutant formation, paving the way for future optimizations in metal combustion technology.

Read the full paper here: https://lnkd.in/ewFzqYj6

A chemical reactor network approach for a gas-assisted iron dust flame in a laboratory-scale combustor, by: Sören Dübal, Pascal Steffens,Johannes MIch, Daniel Braig, Antje Vahl, Leon Loni Berkel, Arne Scholtissek, Tiziano Faravelli, Christian Hasse, Hendrik Nicolai, Sandra Hartl