Entwicklung eines Vorgehensmodells für Systematische Literaturrecherchen unter Einsatz von Large Language Models

Development of a process model for systematic literature searches using large language models

2025/11/25

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisors: Daniel Bentz, M.Sc., Benedikt Engel, M.Sc.

Charakterisierung von Aluminium- und Kupferfolien für Mikroumformprozesse

Characterization of Aluminum and Cupper Foils for Micro forming Processes

2025/11/14

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nicolás Castrillón, M. Sc.

Lernfabrikforschung im Kontext klimaneutraler Produktion

Learning factories in the context of climate neutral production

2025/11/10

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Niklas Bode, M.Sc.

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to predict optimal aircraft catering levels based on data available through the check-in process on a boarding pass. Parameters include names, nationalities, genders, ages, and aircraft destination, for instance. Historical ordering of individuals for a world-wide B787 fleet has been logged in a synthetic database. A Machine Learning (ML) model shall be trained using the boarding pass data to predict flight catering level and analyze the prediction quality. In a second step, an airline dashboard to show ordering fleet prediction using acceptable risk levels shall be designed. The dashboard will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to predict an individuals future ordering based on their personal historical behavior that has been logged in a database. This Machine Learning (ML) model shall use available world-wide B787 synthetic data, augment the data, and train an ML algorithm. With the remaining data the objective is to determine prediction quality. In a second step, an inflight ordering/recording iPhone app for passenger and flight attendants shall be built to demonstrate how the data could be collected. The app will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to build an image recognition collection algorithm to collect inflight food ordering data in a cabin mockup. Images are collected in a galley, on a food trolley, and withing a cabin, the data is then analyzed, and consumption will be identified. The data will be compared to the real consumption. The analysis should be on a cabin and an individual level and not include flight-attendant or passenger intervention. In a second step, an airline dashboard to show consumption levels shall be designed. The dashboard will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Nanostrukturiertes Titan für biomedizinische Implantate – Eine systematische Literaturrecherche zu Verfahren, Eigenschaften und Anwendungen

Nanostructured Titanium for Biomedical Implants – A Systematic Literature Review on Methods, Properties, and Applications

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nick Philippi, M. Sc.

Untersuchung und Vergleich der erreichten Materialeigenschaften bei der Nanostrukturierung von Stahl durch Equal Channel Angular Swaging

Investigation and Comparison of the Achieved Material Properties in the Nanostructuring of Steel by Equal Channel Angular Swaging

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nick Philippi, M. Sc.

Datengetriebe Prozessoptimierung: Einsatz von Machine Learning in flexiblen Prozessen zur Effizienzsteigerung für die Automobilproduktion

Data driven process optimization: Use of machine learning in continuous processes for automotive production

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Benedikt Depta, M. Sc.

Innovative Umformverfahren in der Automobilproduktion: Spaltprofilbiegen für Batteriekästen von Elektrofahrzeugen

Innovative Forming Processes in Automotive Production: Split-Profile Bending for Battery Housings of Electric Vehicles

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Benedikt Depta, M. Sc.

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Sarah Schwindt-Drews

2025/11/04

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Lisa Zeitler

Versuchsdurchführung und Modellbildung zur Prädiktion des Trocknungsergebnis einer Industriellen Reinigungsmaschine

Experimental design and modeling for predicting the drying results of an industrial cleaning machine

2025/10/31

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Jonathan Magin, M.Sc. M.Sc.

Entwicklung und Validierung eines KI-Modells zur Vorhersage tribologischer Lasten für die Kaltmassivumformung

Development and validation of an AI model for predicting tribological loads for cold forging

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Jonas Launhardt, M. Sc.

KI-basierte multivariable Vorhersage und Identifikation optimaler Prozessfenster für Fließpressprozesse

AI-based multivariable prediction and identification of optimal process windows for extrusion processes

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Sven Varchmin, M. Sc.

Transfer Learning zur Übertragung von KI-Modellen auf neue Fließpressprozesse

Transfer learning for transferring AI models to new extrusion processes

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Sven Varchmin, M. Sc.

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

2025/10/23

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Evrim Cicek, M.Sc.

2025/10/13

Within the research project DFG-MiRoVA, the Institute of Automotive Engineering (FZD) develops capability-based modeling for automated driving systems (ADS) beyond SAE levels. This thesis designs and evaluates a method to capture and explain causal relationships between functional scope, the operational design domain (ODD) and the human machine interface (HMI).

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

Im Rahmen des Forschungsprojekts DFG-MiRoVA entwickelt das Fachgebiet für Fahrzeugtechnik (FZD) eine fähigkeitsbasierte Modellierung für automatisierte Fahrsysteme (ADS) über die SAE-Stufen hinaus. Diese Arbeit entwirft und evaluiert eine Methode zur Identifizierung, Klassifizierung und Zuordnung von ADS-Anwendungsfällen zu Funktionsumfang, Systemgrenzen (ODD) und Mensch-Maschine-Schnittstelle (HMI) – einschließlich der Ableitung von Systemanforderungen aus Anwendungsfällen.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

2025/10/13

Im Rahmen des Forschungsprojekts DFG-MiRoVA entwickelt das Fachgebiet für Fahrzeugtechnik (FZD) eine fähigkeitsbasierte Modellierung für automatisierte Fahrsysteme (ADS) über die SAE-Stufen hinaus. Diese Arbeit entwirft und validiert eine Methode zur Erfassung von Migrationsmerkmalen – d. h. wie sich Funktionsumfang, Systemgrenzen (ODD) und Mensch-Maschine-Schnittstelle (HMI) im Laufe der Zeit entwickeln und miteinander interagieren.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Felix Hoffmann

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Felix Hoffmann

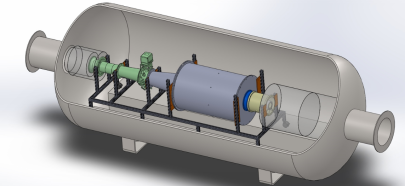

Experimentelle Untersuchung der Parameter zur Reduktion von Eisenpulvern in Wirbelschichtreaktoren unter Verwendung von in-situ Methanreformierung

Experimental Investigation of the Parameters for the Reduction of Iron Powders in Fluidised Bed Reactors utilizing in situ methane reforming

2025/09/30

Fachbereich Maschinenbau, Energiesysteme und Energietechnik (EST)

Supervisor: M.Sc. Balte Johnen

Entwicklung eines Kostenmodells für elektrische Maschinen und der Leistungselektronik von BEV

Institut für Mechatronische Systeme im Maschinenbau

2025/09/18

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Christopher Reus, M.Sc.

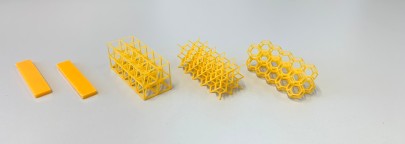

Entwicklung eines 2K-3D-gedruckten aktiv-elastischen Niederhalters zum Tiefziehen von Papier

Development of a 2K-3D-printed active-elastic blankholder for deep drawing of paper

2025/09/12

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Cédric Brunk , M. Sc.

Qualitätssicherung in der additiven Fertigung von Implantaten mittels Prozessüberwachung

Quality assurance in the additive manufacturing of implants using process monitoring

2025/09/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Jana Harbig

Gradierte Oberflächeneigenschaften bei Implantaten in der additiven Fertigung

Graded surface properties in implants manufactured using additive manufacturing

2025/09/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Johanna Gluns, M.Sc.

Fachbereich Maschinenbau, Energiesysteme und Energietechnik (EST)

Supervisors: M.Sc. Matti Löhden, Yannik Lichtmannegger, M.Sc.

Experimentelle Analyse des Wärmeübergangs zwischen festen Kontaktflächen unter Einfluss unterschiedlicher Zwischenstoffe

Experimental Analysis of Heat Transfer Between Solid Contact Surfaces Under the Influence of Different Interfacial Materials

2025/09/05

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisors: Johannes Bruder, M. Sc., Tim Schmitt, M. Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Lina Kramer, M.Sc.

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Christian Gutzler, M.Sc.

2025/09/03

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Christian Gutzler, M.Sc.

Meshfreie Simulation von Überflutungen nach Starkregenereignissen mit Open-Source-Software

Mesh-free simulation of flooding following heavy rainfall using open-source software.

2025/09/02

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Dr.-Ing. Maximilian Kuhr

Experimentelle Untersuchung von Pumpenverschleiß in partikelbeladenen Medien

Experimental analysis of pump wear in particle laden fluids

2025/09/02

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Pascal Moor, M.Sc.

Experimentelle Untersuchung verschiedener Fasersuspensionen in einer turbulenten Strömung über einer Rückwärtssprungstufe

Experimental study of various fiber suspensions in a turbulent backward-facing step flow

2025/08/28

Fachbereich Maschinenbau, Papierfabrikation und Mechanische Verfahrenstechnik (PMV)

Supervisor: M.Sc. Furui Yin

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Lina Kramer, M.Sc.

Modellierung des Ressourcenverbrauchs eines Roboterbasierten Fertigungssystems für die Automatisierte Ökobilanzierung hybrid Gefertigter Bauteile

Modeling the resource consumption of a robot-based manufacturing system for automated life cycle assessment of hybrid manufactured components

2025/08/20

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Jonas Zarges, M.Sc., Edward Schreiner, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Gilbert Ely Engert, M.Sc.

2025/08/07

Iron is considered as a promising energy carrier in metal-based energy storage cycles, where energy is released via thermochemical oxidation. As part of this thesis, a laser system for the controlled ignition of single levitated iron particles will be developed, constructed, and commissioned to enable their elemental analysis during combustion using Laser-Induced Breakdown Spectroscopy (LIBS).

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: M.Sc. Nils Oberndorfer

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Felix Friedrich

Repräsentation von Standardarbeitsblättern als Knowledge-Graphen mithilfe von Machine Learning Algorithmen

Representing Standard Worksheets as Knowledge-Graph Embeddings using Machine Learning Algorithms

2025/08/01

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisors: Lukas Hammen, M.Sc. , Stefan Schulte, M.Sc.

2025/07/25

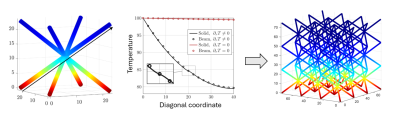

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Dominik Klein

2025/07/25

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Juan Camilo Alzate Cobo

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Yusuf Elbadry

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Nico Bürger, M.Sc.

Erarbeitung von Anforderungen und Lastenheft Für ein Mes-System zur Unterstützung resilienter Fertigung

Development of requirements and specifications for a measurement system to support resilient manufacturing

2025/07/15

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Augustino Doan, M.Sc., Leonie Meldt, M.Sc.

Status Quo der kundenindividuellen Produktion in Zeiten des Mass Individualisation – Eine systematische Literaturanalyse

Status quo of customized production in times of mass individualization – a systematic literature analysis

2025/07/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Benedikt Engel, M.Sc.

Produktlösungsraum und Fertigungsfähigkeiten zusammenbringen – Eine systematische Literaturanalyse

Bringing product solution space and manufacturing capabilities together – A systematic literature review

2025/07/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Benedikt Engel, M.Sc.

Systematische Untersuchung der autonomen Fertigung: Analyse bestehender Submodelle und Identifikation von Forschungslücken

Systematic investigation of autonomous manufacturing: Analysis of existing submodels and identification of research gaps

2025/07/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Ann-Kathrin Bischoff, M.Sc.

Marktstudie zu Einflussgrößen von Wälzlagern

Market study on factors influencing rolling bearings

2025/07/02

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Christiane Melzer, M.Sc.

Digital image correlation

Plasticity identification and crack tip parameter calculation

2025/06/11

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Anatoly Zaiat, M.Sc.

Rising product complexity, shorter development cycles, and sustainability demands are driving automation in product development. AI-based generative design, especially in topology optimization, offers efficient ways to explore complex design spaces and enable largely automated processes.

Product Life Cycle Management

Supervisor: Jonas Voges, M. Sc.

Weiterentwicklung eines Prozessmodels für Wirbelschichtvergasung von Biomasse in Aspen Plus

Development of a process model for fluidized bed gasification of biomass in Aspen Plus

2025/05/12

Techno-Economic Analysis and Optimization of Hybrid Absorption Processes for CO2 Capture from Lime and Cement Plants

Technisch-wirtschaftliche Bewertung und Optimierung hybrider Absorptionsverfahren zur CO2-Abscheidung aus Kalk- und Zementwerken

2025/01/24

Fachbereich Maschinenbau, Energiesysteme und Energietechnik (EST)

Supervisor: Dr.-Ing. Martin Nicolas Greco Coppi

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: Dr.-Ing. Tao Li

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: Dr.-Ing. Tao Li

The evaporation of liquid droplets, a phenomenon ubiquitous in daily life, has garnered significant attention in scientific research. Of particular interest is the evaporation of droplets laden with nonvolatile solutes, which results in intricate deposition patterns on the substrate. Understanding the mechanisms underlying the formation of these patterns is crucial for various technical applications, spanning from coating and inkjet printing to disease detection. This work delves into the development of a comprehensive model of the specific ring-like deposition patterns observed during the drying of droplets.

Fachbereich Maschinenbau, Technische Thermodynamik (TTD)

Supervisor: Amirhossein Khazayialiabad, M.Sc.

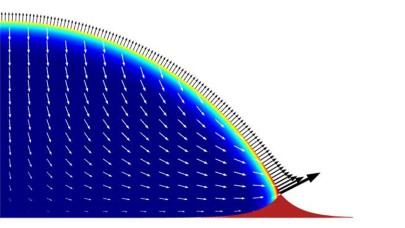

As emission regulations tighten and policies evolve to address global climate change, reducing pollutant and greenhouse gas emissions has become a top priority in combustion research. The advanced combustion concept of matrix-stabilized combustion is essential for achieving low emissions and improved flame stabilization in fuel-lean conditions. Combustion within an inert porous matrix differs significantly from conventional burners that use a free flame. Porous media burners (PMBs) rely on the principle that the solid porous matrix internally recirculates heat from combustion products back to the reactants. This internal heat recirculation in PMBs lowers the lean flammability limit of fuel-air mixtures, enabling lower emissions, reduced thermal stresses due to lower flame temperatures, and complete fuel conversion through lean combustion. However, stabilizing these flames within the porous matrix poses challenges due to the complex thermophysical, transport, and heat-transfer processes involved.

The objective of this project is to install a well-designed PMB in the RSM laboratories and perform the first experimental investigation using different pore structures and fuel mixtures.

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: Dr.-Ing. Tao Li

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisors: Josef Schönherr, M.Sc., Dr.-Ing. Marius Hofmann

Druckmaschinen und Druckverfahren (IDD)

Supervisor: Annabelle Neuhäusler, M.Sc.

Experimentelle Charakterisierung der Material- und Struktureigenschaften beim Graustufen-MSLA-3D-Druck

Master/Bachelor-Thesis (Maschinenbau / Mechanik / Computational Engineering)

2021/03/09

Fachbereich Maschinenbau

Inbetriebnahme und Kennlinienmessung eines Axialventilatorprüfstandes

Commissioning and measurement of fan characteristics of an axial fan

2017/12/07

Supervisor: Sebastian Saul, M.Sc.

Numerische und experimentelle Untersuchungen eines bistabilen Energy-Harvesters

Numerical and experimental Investigations on a bistable Energy Harvester

2014/10/27

Numerische Berechnungsverfahren im Maschinenbau (FNB)

Supervisor: Dr.-Ing. Matthias Heymanns

Studentische Arbeiten am Fachgebiet pmd

Theses at the Institute for Product Development and Machine Elements (pmd)

2012/04/29

Maschinenbau

Project work and final theses

Bachelor theses

Project work and final theses

Bachelor theses

Currently advertised Bachelor's theses

Here you will find an overview of all the current offers for Bachelor's theses in the various fields of mechanical engineering. And if there is nothing suitable for you, simply contact the staff of the departments you are interested in directly.