Einsatz von Reinforcement-Learning in hochflexiblen Prozessen zur modellbasierten Vorhersage von Zustellkurven für die Automobilproduktion

Application of Reinforcement Learning in Highly Flexible Processes for Model-Based Prediction of Feed Curves in Automotive Production

2025/11/20

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisors: Benedikt Depta, M. Sc., Ciarán Veitenheimer, M. Sc.

Degradationsberücksichtigung in Betriebsstrategien von Brennstoffzellenfahrzeugen

Institut für Mechatronische Systeme im Maschinenbau

2025/11/19

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Dominik Leininger, M.Sc.

Langfristige online-fähige Betriebsstrategien für Brennstoffzellenfahrzeuge

Institut für Mechatronische Systeme im Maschinenbau

2025/11/19

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Dominik Leininger, M.Sc.

Thermalsysteme von Brennstoffzellenfahrzeugen: Modellintegration und Betriebsstrategieanpassung

Institut für Mechatronische Systeme im Maschinenbau

2025/11/19

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Dominik Leininger, M.Sc.

Charakterisierung von Aluminium- und Kupferfolien für Mikroumformprozesse

Characterization of Aluminum and Cupper Foils for Micro forming Processes

2025/11/14

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nicolás Castrillón, M. Sc.

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: M.Sc. Clemens Hansemann

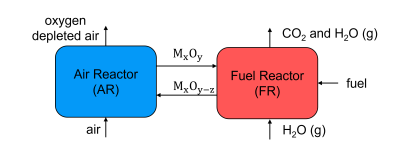

Climate Mitigation with Low-Cost Negative Emissions of CO2 using CLC – Pilot Operation with Novel Oxygen Carrier

MSc work at Chalmers University of Technology, Göteborg, Schweden

2025/11/10

Spray impact on thin wall films is an important process in many industrial applications e.g. spray cooling or internal combustion. In this process the single drop impact is an integral part. The drop impact is shaped by hydro- and thermodynamic mechanisms. One of the outcomes is a corona splash where numerous secondary drops are developing which can have a significant influence on the overall process. Its understanding and prediction therefore is of great importance.

This thesis involves the investigation of the corona splash experimentally. With an already existing experimental setup with high-speed imaging, drop impact experiments should be performed. The operational parameters should be varied systematically to investigate different influences. This is achieved by using different liquids (water, silicone oils, etc.) and by changing other parameters like film temperature, film thickness etc. Afterwards the measurements are evaluated with image processing algorithms. A focus of the evaluation lies in extending existing models for the splashing threshold and additionally in analyzing the secondary spray (drop size and velocity distribution).

Strömungslehre und Aerodynamik (SLA), Fachbereich Maschinenbau

Supervisor: Lukas Weimar , M.Sc.

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to predict optimal aircraft catering levels based on data available through the check-in process on a boarding pass. Parameters include names, nationalities, genders, ages, and aircraft destination, for instance. Historical ordering of individuals for a world-wide B787 fleet has been logged in a synthetic database. A Machine Learning (ML) model shall be trained using the boarding pass data to predict flight catering level and analyze the prediction quality. In a second step, an airline dashboard to show ordering fleet prediction using acceptable risk levels shall be designed. The dashboard will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to predict an individuals future ordering based on their personal historical behavior that has been logged in a database. This Machine Learning (ML) model shall use available world-wide B787 synthetic data, augment the data, and train an ML algorithm. With the remaining data the objective is to determine prediction quality. In a second step, an inflight ordering/recording iPhone app for passenger and flight attendants shall be built to demonstrate how the data could be collected. The app will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Airline catering, which includes food and beverage (F&B) services, plays a crucial role in shaping the passenger experience. Many travelers discuss the quality of the onboard F&B services. Excessive catering can result in significant waste, while insufficient catering can lead to unhappy passengers. According to IATA estimates, between $2 billion and $3 billion worth of F&B items are wasted each year. Moreover, the weight of unused F&B items contributes to unnecessary fuel consumption.

To address this issue, solutions can be found in determining optimal catering levels for every flight. The primary challenge is to gather objective data or develop a reliable model. Various concepts exist for collecting data on individual pre-, in-, or post-flight orders, utilizing behavioral analytics, or employing generic route modeling.

In this thesis:

The aim of this thesis is to build an image recognition collection algorithm to collect inflight food ordering data in a cabin mockup. Images are collected in a galley, on a food trolley, and withing a cabin, the data is then analyzed, and consumption will be identified. The data will be compared to the real consumption. The analysis should be on a cabin and an individual level and not include flight-attendant or passenger intervention. In a second step, an airline dashboard to show consumption levels shall be designed. The dashboard will be integrated into the TU-Darmstadt cabin simulator software environment.

Fachbereich Maschinenbau, Flugsysteme und Regelungstechnik (FSR)

Supervisors: M.Sc. Florian Coors, Prof. Dr.-Ing. Jens Schiefele

Messung der Wirkung einer adaptiven ergonomischen Arbeitsstation auf die physische Belastung und den Bewegungsspielraum mit einem Motion Capture System

2025/11/06

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Maximilian Pätzold

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Maximilian Pätzold

Nanostrukturiertes Titan für biomedizinische Implantate – Eine systematische Literaturrecherche zu Verfahren, Eigenschaften und Anwendungen

Nanostructured Titanium for Biomedical Implants – A Systematic Literature Review on Methods, Properties, and Applications

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nick Philippi, M. Sc.

Untersuchung und Vergleich der erreichten Materialeigenschaften bei der Nanostrukturierung von Stahl durch Equal Channel Angular Swaging

Investigation and Comparison of the Achieved Material Properties in the Nanostructuring of Steel by Equal Channel Angular Swaging

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Nick Philippi, M. Sc.

Aufbau und Umsetzung einer Simulationsumgebung für die Bewegungs- und Prozesssimulation des roboterbasierten DED-LB

Development and implementation of a simulation environment for motion and process simulation of the robot-based DED-LB

2025/11/06

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Fabian Kalter, M.Sc.

Datengetriebe Prozessoptimierung: Einsatz von Machine Learning in flexiblen Prozessen zur Effizienzsteigerung für die Automobilproduktion

Data driven process optimization: Use of machine learning in continuous processes for automotive production

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Benedikt Depta, M. Sc.

Innovative Umformverfahren in der Automobilproduktion: Spaltprofilbiegen für Batteriekästen von Elektrofahrzeugen

Innovative Forming Processes in Automotive Production: Split-Profile Bending for Battery Housings of Electric Vehicles

2025/11/06

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Benedikt Depta, M. Sc.

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Sarah Schwindt-Drews

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Sarah Schwindt-Drews

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Sarah Schwindt-Drews

Data Augmentation und synthetische daten in der Prädiktion der Bauteiltrockenheit

Data augmentation and synthetic data in predicting component dryness

2025/10/31

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Jonathan Magin, M.Sc. M.Sc.

Entwicklung und vergleich von Grey-Box Modellen in der Bauteiltrocknung

Development and comparison of gray-box models in component drying

2025/10/31

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Jonathan Magin, M.Sc. M.Sc.

Liquid bridge breakup is a fascinating process with applications in microfluidics, printing, and wetting. While the classical problem involves a liquid bridge surrounded by another fluid (like air or oil), in this project we focus on a different case: liquid bridges on solid surfaces. These systems introduce new physics, particularly at the interface between the liquid and the solid.

In previous works, we’ve looked into how viscosity affects the breakup of these bridges. We also know that the surface properties of the solid play a role. But now we want to go a step further: what happens when the liquid contains salt?

Fachbereich Maschinenbau, Nano- und Mikrofluidik (NMF)

Supervisor: Salar Jabbary Farrokhi, M.Sc.

Systemzuverlässigkeit, Adaptronik und Maschinenakustik (SAM)

Supervisor: Dr.-Ing. Sören Wenzel

Im Rahmen des Projekts DaCCCar wird am Fachgebiet Fahrzeugtechnik (FZD) an der Entwicklung von langlebigen Fahrzeugkonzepten geforscht. Ziel dieser Arbeit ist es, die regulatorischen Anforderungen zur Durchführung von nachträglichen Änderungen an Pkw zu erfassen. Für diesen Rahmen sollen anschließend domänenübergreifend Geschäftsmodelle identifiziert und hinsichtlich ihrer Eignung analysiert werden.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Jörn Hasenkrug, M.Sc.

Introduction text (teasertext)

The growing complexity of automated driving demands scalable pipelines to extract relevant traffic scenes from real-world data automatically. This work, in collaboration with Porsche Engineering, explores how state-of-the-art Vision-Language Models can identify and retrieve predefined driving scenarios in large-scale datasets.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Anton Kuznietsov, M.Sc.

2025/10/27

Im Rahmen des Forschungsprojekts DFG-MiRoVA entwickelt das Fachgebiet Fahrzeugtechnik (FZD) Ansätze zur Simulation des Fahrverhaltens von automatisierten Fahrzeugen. Diese Arbeit entwickelt und evaluiert ein kompaktes Echtzeitmodell für das Fahrverhalten automatisierter Fahrzeuge durch Destillation aus einem vortrainierten Vision-Language-Modell unter Verwendung bereitgestellter Verkehrsszenarien.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

In collaboration with the Institute for Product Development and Machine Elements (PMD), a new research initiative is being launched in the field of Circular Software Defined Products (CSDP). The aim of this work is to systematically review the current state of research and identify key characteristics, requirements, and design criteria that contribute to the development of CSDP.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD), Produktentwicklung und Maschinenelemente (pmd)

Supervisors: Can Kemmler, M.Sc., Marius Crucius-Kilian, M.Sc.

Entwicklung und Validierung eines KI-Modells zur Vorhersage tribologischer Lasten für die Kaltmassivumformung

Development and validation of an AI model for predicting tribological loads for cold forging

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Jonas Launhardt, M. Sc.

KI-basierte multivariable Vorhersage und Identifikation optimaler Prozessfenster für Fließpressprozesse

AI-based multivariable prediction and identification of optimal process windows for extrusion processes

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Sven Varchmin, M. Sc.

Transfer Learning zur Übertragung von KI-Modellen auf neue Fließpressprozesse

Transfer learning for transferring AI models to new extrusion processes

2025/10/24

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisor: Sven Varchmin, M. Sc.

Entwicklung eines Tools zur Prognose von Verbräuchen von Bussen

Institut für Mechatronische Systeme im Maschinenbau

2025/10/23

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisors: Adel Turić, M.Sc., Paul Heckelmann

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

2025/10/23

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Marius Crucius-Kilian, M.Sc.

2025/10/20

The energy transition requires new technologies to efficiently utilize CO₂-free energy carriers. Within the European research project HYROPE, an innovative two-stage combustion concept for hydrogen gas turbines is being developed. The aim of this thesis is the design and construction of a test rig to investigate hydrogen autoignition processes. A particular focus of the work is on conducting flame stability tests, flow measurements, and the additive manufacturing of the burner.

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: M.Sc. Maren Werner

2025/10/20

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Pia-Sophie Becks

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Evrim Cicek, M.Sc.

Anwendung kausaler Inferenzmethoden zur datengetriebenen Prozessoptimierung in der additiven Fertigung

Application of causal inference methods for data-driven process optimization in additive manufacturing

2025/10/15

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Josef Lee, M.Sc., Daeyeop Na, M.Sc.

Wirtschaftslichkeitsbewertung von Chacos Engineering in der industriellen Produktion

Economic evaluation of chaos engineering in industrial production

2025/10/15

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), MiP | Management industrieller Produktion

Supervisors: Leonie Meldt, M.Sc., Augustino Doan, M.Sc.

2025/10/13

Within the research project DFG-MiRoVA, the Institute of Automotive Engineering (FZD) develops capability-based modeling for automated driving systems (ADS) beyond SAE levels. This thesis designs and evaluates a method to capture and explain causal relationships between functional scope, the operational design domain (ODD) and the human machine interface (HMI).

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

Im Rahmen des Forschungsprojekts DFG-MiRoVA entwickelt das Fachgebiet für Fahrzeugtechnik (FZD) eine fähigkeitsbasierte Modellierung für automatisierte Fahrsysteme (ADS) über die SAE-Stufen hinaus. Diese Arbeit entwirft und evaluiert eine Methode zur Identifizierung, Klassifizierung und Zuordnung von ADS-Anwendungsfällen zu Funktionsumfang, Systemgrenzen (ODD) und Mensch-Maschine-Schnittstelle (HMI) – einschließlich der Ableitung von Systemanforderungen aus Anwendungsfällen.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

2025/10/13

Im Rahmen des Forschungsprojekts DFG-MiRoVA entwickelt das Fachgebiet für Fahrzeugtechnik (FZD) eine fähigkeitsbasierte Modellierung für automatisierte Fahrsysteme (ADS) über die SAE-Stufen hinaus. Diese Arbeit entwirft und validiert eine Methode zur Erfassung von Migrationsmerkmalen – d. h. wie sich Funktionsumfang, Systemgrenzen (ODD) und Mensch-Maschine-Schnittstelle (HMI) im Laufe der Zeit entwickeln und miteinander interagieren.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Can Kemmler, M.Sc.

Autonome Fertigung vernetzt denken: Entwicklung eines interaktiven submodell- Netzwerks

Thinking autonomously about networked manufacturing: Development of an interactive submodel network

2025/10/07

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Ann-Kathrin Bischoff, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Felix Hoffmann

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Felix Hoffmann

Externe Masterarbeit bei Bürkert: Validierung eines Sim2Real-Ansatzes für Reinforcement Learning-basierte Massendurchflussregelungen

Validation of a Sim2Real approach for Reinforcement Learning-based mass flow control

2025/10/01

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Tobias Meck, M.Sc.

2025/10/01

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), MiP | Management industrieller Produktion

Supervisor: Alexander Moltschanov, M.Sc.

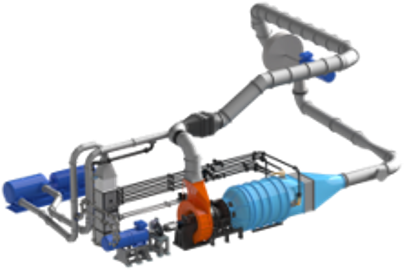

Experimentelle Untersuchung der Parameter zur Reduktion von Eisenpulvern in Wirbelschichtreaktoren unter Verwendung von in-situ Methanreformierung

Experimental Investigation of the Parameters for the Reduction of Iron Powders in Fluidised Bed Reactors utilizing in situ methane reforming

2025/09/30

Fachbereich Maschinenbau, Energiesysteme und Energietechnik (EST)

Supervisor: M.Sc. Balte Johnen

2025/09/26

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: M.Sc. Leon Schuhmann

Entwicklung von FFF gedruckten Scaffolds für die regenerative Medizin

Development of FFF printed scaffolds for regenerative medicine

2025/09/23

With FullControl G-code, the FFF printing process can be fully customized. All relevant parameters such as travel distance, extrusion factor and printing speed can be precisely controlled. This flexibility opens up the possibility of using normally undesirable phenomena such as stringing as a targeted design element. In previous projects, flexible, textile-like structures have already been reproduced in this way (see image). Future work will combine this design freedom with the customizability of FFF printing to not only reproduce existing structures, but also to develop completely new scaffolds. The aim of this thesis is to design implantable, flexible and highly porous scaffolds for tissue engineering and to investigate their influence on cell behavior.

Fachbereich Maschinenbau, Druckmaschinen und Druckverfahren (IDD)

Supervisor: Sebastian Scholpp, M.Sc.

Entwicklung eines Kostenmodells für elektrische Maschinen und der Leistungselektronik von BEV

Institut für Mechatronische Systeme im Maschinenbau

2025/09/18

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Christopher Reus, M.Sc.

Multikriterielle Optimierung von mehrgängigen und zweimotorigen elektrischen Antriebssträngen

Institut für Mechatronische Systeme im Maschinenbau

2025/09/18

Robots are extremely versatile machines with almost endless application possibilities. In the course of an exhibition, a prototype demonstrator of these diverse applications was developed, in which our 7-axis collaborative robot arm ‘Rica’ is used to draw faces. Images are converted into line drawings and paths to be traversed are calculated from them. This demonstrator is now to be further developed and upgraded.

Institut für Mechatronische Systeme im Maschinenbau (IMS), Fachbereich Maschinenbau

Supervisor: Christopher Reus, M.Sc.

Qualitätssicherung in der additiven Fertigung von Implantaten mittels Prozessüberwachung

Quality assurance in the additive manufacturing of implants using process monitoring

2025/09/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Dr.-Ing. Jana Harbig

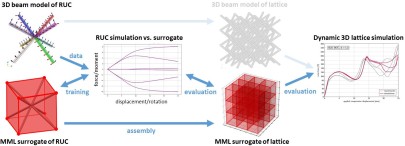

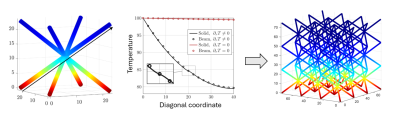

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Dominik Klein

Gradierte Oberflächeneigenschaften bei Implantaten in der additiven Fertigung

Graded surface properties in implants manufactured using additive manufacturing

2025/09/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Johanna Gluns, M.Sc.

Schätzung von Produktionszeiten für Neuteile und Integration in den Auftragsanlageprozess

Estimation of production times for new parts and integration into the order creation process

2025/09/11

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisors: Stefan Schulte, M.Sc., Benedikt Engel, M.Sc.

Fachbereich Maschinenbau, Energiesysteme und Energietechnik (EST)

Supervisors: M.Sc. Matti Löhden, Yannik Lichtmannegger, M.Sc.

Due to the escalating extreme weather conditions, the aircraft icing events are increasingly growing. The analysis of this phenomenon has gained increased attention, particularly in the field of aviation safety. A significant contributor to icing is the occurrence of Supercooled Large Droplets (SLD), water droplets suspended in air at temperatures below freezing one. Previous experiments in the scientific community have predominantly focused on the normal impact of these droplets on solid surfaces with low velocities.

Our research aims to expand this understanding by considering rotating surfaces and high relative impact velocities. This approach will closely simulate real-world conditions that an aircraft wing's experience.

The project consists of using an existing single-water-drop impact set-up with a rotating disk and measuring, by means of a chromatic line sensor (CLS), the thickness of the ice layer formed on the disk.

Fachbereich Maschinenbau, Strömungslehre und Aerodynamik (SLA)

Supervisor: Reda Kamal, M.Sc.

Extreme weather conditions are increasingly contributing to aircraft icing events, which pose significant safety risks. The analysis of this phenomenon has gained increased attention, particularly in the field of aviation safety.

Our research aims to better understand the involved phenomena by analyzing the single drop impact on moving surfaces at high relative impact velocities and the associated heat transfer. This approach will closely simulate the real-world conditions that aircraft wings experience.

The project involves simulating the conjugate heat-transfer of a single water drop impact onto a moving substrate to replicate existing infrared-imaging experimental data.

Fachbereich Maschinenbau, Strömungslehre und Aerodynamik (SLA)

Supervisor: Reda Kamal, M.Sc.

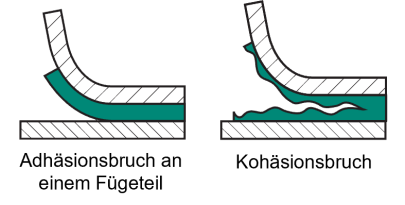

Experimentelle Analyse des Wärmeübergangs zwischen festen Kontaktflächen unter Einfluss unterschiedlicher Zwischenstoffe

Experimental Analysis of Heat Transfer Between Solid Contact Surfaces Under the Influence of Different Interfacial Materials

2025/09/05

Fachbereich Maschinenbau, Produktionstechnik und Umformmaschinen (PtU)

Supervisors: Johannes Bruder, M. Sc., Tim Schmitt, M. Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), ETA | Energietechnologien und Anwendungen in der Produktion

Supervisor: Lina Kramer, M.Sc.

Prozessüberwachung in der additiven Fertigung: Feature-Engineering zur Defektquantifizierung

Process monitoring in additive manufacturing: Feature-Engineering for defect quantification

2025/09/05

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Jonathan Utsch, M.Sc.

Am Fachgebiet Fahrzeugtechnik (FZD) wird in Kooperation mit der valantic Software & Technology Innovations GmbH an der Simulation von Sensorik für die Umfelderfassung automatisierter Fahrzeuge geforscht. Im Rahmen dieser Masterthesis soll untersucht werden, inwiefern sich bestehende Simulationsplattformen aus dem Automobilbereich auf andere Domänen (z. B. Bahn, Landwirtschaft, Bauwesen) übertragen lassen.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisor: Kristof Hofrichter, M.Sc.

Research on the topic of sensor data generation in automated driving is being conducted at the Institute of Automotive Engineering Darmstadt (FZD) in collaboration with Porsche Engineering. In this thesis, it will be researched to what extent NVIDIA Omniverse can be used to generate sensor data for automated driving.

Fachbereich Maschinenbau, Fahrzeugtechnik (FZD)

Supervisors: Kristof Hofrichter, M.Sc., Dr.-Ing. Kai Storms

Fachbereich Maschinenbau, Produktentwicklung und Maschinenelemente (pmd)

Supervisor: Christian Gutzler, M.Sc.

Meshfreie Simulation von Überflutungen nach Starkregenereignissen mit Open-Source-Software

Mesh-free simulation of flooding following heavy rainfall using open-source software.

2025/09/02

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Dr.-Ing. Maximilian Kuhr

Weiterentwicklung einer modularen Simulationsumgebung für Luftfederdämpfer

Further development of a modular simulation environment for air spring dampers

2025/09/02

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Ingo Dietrich, M.Sc.

Experimentelle Untersuchung von Pumpenverschleiß in partikelbeladenen Medien

Experimental analysis of pump wear in particle laden fluids

2025/09/02

Fachbereich Maschinenbau, Institut für Fluidsystemtechnik (FST)

Supervisor: Pascal Moor, M.Sc.

2025/09/01

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Pia-Sophie Becks

Hydrogen combustion in the spark-ignited optical RSM engine is currently being investigated using a variety of fuel delivery methods (premixed, PFI, DI). With the focus on flame propagation and NOx emissions, LIF is selected to investigate fuel-air mixing before and after ignition.

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisors: Dr. ir. Max Peters, M.Sc. İrem Alp

Experimentelle Untersuchung verschiedener Fasersuspensionen in einer turbulenten Strömung über einer Rückwärtssprungstufe

Experimental study of various fiber suspensions in a turbulent backward-facing step flow

2025/08/28

Fachbereich Maschinenbau, Papierfabrikation und Mechanische Verfahrenstechnik (PMV)

Supervisor: M.Sc. Furui Yin

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Lina Kramer, M.Sc.

Modellierung des Ressourcenverbrauchs eines Roboterbasierten Fertigungssystems für die Automatisierte Ökobilanzierung hybrid Gefertigter Bauteile

Modeling the resource consumption of a robot-based manufacturing system for automated life cycle assessment of hybrid manufactured components

2025/08/20

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Jonas Zarges, M.Sc., Edward Schreiner, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Gilbert Ely Engert, M.Sc.

2025/08/07

Iron is considered as a promising energy carrier in metal-based energy storage cycles, where energy is released via thermochemical oxidation. As part of this thesis, a laser system for the controlled ignition of single levitated iron particles will be developed, constructed, and commissioned to enable their elemental analysis during combustion using Laser-Induced Breakdown Spectroscopy (LIBS).

Fachbereich Maschinenbau, Reaktive Strömungen und Messtechnik (RSM)

Supervisor: M.Sc. Nils Oberndorfer

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Gilbert Ely Engert, M.Sc.

Fachbereich Maschinenbau, Institut für Arbeitswissenschaft (IAD)

Supervisor: M.Sc. Felix Friedrich

Automatische Anleitungserstellung aus Videos mithilfe von ressourcenarmen Computer Vision und Machine Learning Algorithmen

Enabling Automatic Instruction Generation from Videos using Lightweight Computer Vision and Machine Learning Algorithms

2025/08/01

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Lukas Hammen, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisor: Gilbert Ely Engert, M.Sc.

Repräsentation von Standardarbeitsblättern als Knowledge-Graphen mithilfe von Machine Learning Algorithmen

Representing Standard Worksheets as Knowledge-Graph Embeddings using Machine Learning Algorithms

2025/08/01

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisors: Lukas Hammen, M.Sc. , Stefan Schulte, M.Sc.

2025/07/25

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Dominik Klein

2025/07/25

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Juan Camilo Alzate Cobo

Cyber-Physische Simulation (CPS)

Supervisors: Prof. Dr. rer. nat. Oliver Weeger, M.Sc. Yusuf Elbadry

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Nico Bürger, M.Sc.

Decarbonizing the chemical industry is a key challenge on the path to CO2 neutrality. For this reason, we are working in the BMBF-funded future cluster ETOS on the transformation of the chemical industry towards more climate-friendly electrochemical technologies.

In this work, the wetting of abstract gauze structures is to be investigated using numerical simulation with OpenFOAM. In particular, the influence of different orifice geometries and wetting properties on the forming phase boundary and a possible bubble formation at too high differential pressures shall be investigated.

Fachbereich Maschinenbau, Nano- und Mikrofluidik (NMF)

Supervisor: Alexander Wagner, M. Sc.

Situative Problemlösung durch large language models

Situational problem solving using large language models

2025/07/09

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisor: Jan Chytraeus, M.Sc.

Numerischer Vergleich eines Reynolds-skalierten mit einem Mach-ähnlichen Turbinenrotor einer Hochdruckturbine

Numeric Comparison of a Reynolds-scaled turbine rotor with a Mach-similar turbine rotor of a high-pressure turbine

2025/06/26

Fundamental investigations into flow phenomena and interaction mechanisms in modern high-pressure turbines are carried out at the Large Scale Turbine Rig (LSTR). The focus is on a Reynolds-scaled high-pressure turbine rotor, which was scaled using a Mach-like high-pressure turbine test rig. Reynolds scaling offers decisive advantages for experimental investigations, but does not reproduce Mach number effects.

Fachbereich Maschinenbau, Gasturbinen, Luft- und Raumfahrtantriebe (GLR)

Supervisor: Dominik Ade, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Edward Schreiner, M.Sc., Christopher Krebs, M.Sc.

Digital image correlation

Plasticity identification and crack tip parameter calculation

2025/06/11

Fachbereich Maschinenbau, Werkstoffkunde (MPA-IfW), Institut für Werkstoffkunde (IfW)

Supervisor: Anatoly Zaiat, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), CiP | Center für industrielle Produktivität

Supervisors: Yuxi Wang, M.Sc., Stefan Schulte, M.Sc.

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Peter Gross, M.Sc., Magnus von Elling, M.Sc.

Deep Learning gestützte Sensibilitätsanalyse zur Bewertung struktureller Beanspruchbarkeit von Konstruktionen

Deep learning-based sensitivity analysis for the evaluation of mechanical resilience of design elements

2025/05/15

The efficient assessment of a component’s structural integrity using deep learning enables the joint optimization of material selection and distribution. This allows for a more flexible and exploratory design space exploration, fostering the development of more holistic design solutions.

Product Life Cycle Management

Supervisor: Jonas Voges, M. Sc.

Weiterentwicklung eines Prozessmodels für Wirbelschichtvergasung von Biomasse in Aspen Plus

Development of a process model for fluidized bed gasification of biomass in Aspen Plus

2025/05/12

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Ann-Kathrin Bischoff, M.Sc., Gilbert Ely Engert, M.Sc.

2025/04/22

Fachbereich Maschinenbau, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW), TEC | Fertigungstechnologie

Supervisors: Ann-Kathrin Bischoff, M.Sc., Lina Kramer, M.Sc.

Maschinenbau

Project work and final theses

Master theses

Project work and final theses

Master theses

Currently advertised Master's theses

Here you will find an overview of all the current offers for Master's theses in the various fields of mechanical and aerospace engineering. And if there is nothing suitable for you, simply contact the staff of the departments you are interested in directly.